Check out this Bellingham chocolate factory, the largest in the Northwest, with a fair trade focus

Inside Look is a Bellingham Herald series where we take readers behind the scenes at restaurants, new businesses, local landmarks and news stories.

A Bellingham chocolate factory has now become the largest chocolate maker in the Pacific Northwest, crafting its organic delicacies along the entire bean-to-chocolate process and giving us a look inside its factory.

K’UL Chocolate, which is Mayan for “the energy and interconnectivity between all living things,” opened in 2018 and now has a 16,000-square-foot facility near the Bellingham Airport that produced more than 300,000 pounds of chocolate chips in 2023.

The delicious company was started by husband-and-wife team Paul Newman and Ari Lee-Newman. The pair visited Peru and the Dominican Republic and were inspired by some of the area’s cacao bean enterprises.

“Initially working with these two origins raised our awareness of the impact of working and supporting women producers at origin,” Paul Newman wrote in an email to The Bellingham Herald. “Our mission is to work directly with women producers and small farmers worldwide. We believe that if we put our energy into directly supporting women, we will help break the cycle of generational poverty. Over time, we have witnessed that investing in women means you are also investing in their families and communities.”

K’UL then developed a simple direct trade sourcing model with its partners across the world.

“By working directly with partners at origin, they source cocoa from six countries, including Dominican Republic, Ghana, Ecuador, Peru, and Uganda and ensure additional premiums are paid that go above organic and fair-trade standards,” according to a news release from the company.

The company works directly with cacao producers around the world to not only ensure a quality product, but to support the farmers themselves.

“The principal of working directly with cacao producers embodies the founders’ mission to reject the status quo by paying farmers fairly, visiting and vetting them in person, and listening and responding to their needs,” Ari Lee-Newman wrote in the news release.

K’UL Chocolate became the largest chocolate maker after a competitor closed down its local operations in September 2023. Since the closure, K’UL Chocolate has been given more opportunities to expand its collaboration with the Pacific Northwest food industry.

“We obviously loved chocolate and were fascinated by how it tasted, made us feel, and made others feel. Most importantly, we wanted to create a product that did good, worked towards elevating people at origin, and provided consumers with a method of participating in doing the same good work by voting with their purchases and buying our product,” Paul Newman to The Herald.

Now, K’UL supplies chocolate to restaurants across the state, partners with Molly Moon’s, a Seattle-based ice cream maker, and is the exclusive chocolate supplier for PCC Markets commissary kitchens, according to the news release.

Local Bellingham businesses have also partnered with K’UL Chocolate. They include Pure Bliss Bakery, Sweet As Waffles, Bellingham’s Community Food Co-Op bakery, Mallard Ice Cream, Raven Breads and Erin Bakers Cookies.

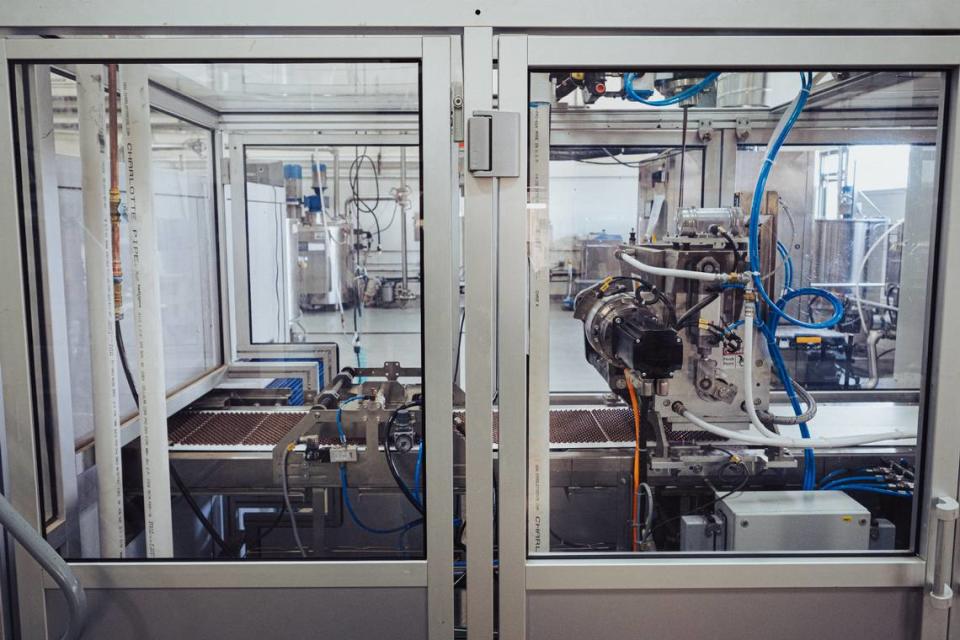

K’UL Chocolate is not only recognized for its fair trade origins but for its extensive process of crafting chocolate.

“We nurture, monitor, and control every single step of the process, unlike the common practice of melting pre-purchased chocolate,” Paul Newman wrote in the news release.

The chocolate-making process starts at its origin and then goes into a fermentation stage, where the beans are placed in wooden boxes or mounts of wet cacao and covered for 5 to 7 days, Paul Newman wrote. The fermented cacao is then dried in hot houses or is solar-dried for up to a week. The dried cacao is then sent directly to K’UL’s factory in Bellingham.

“To understand chocolate-making one needs to lean more into alchemy than science. In order to fully control the chocolate-making process, K’UL’s factory runs ‘roast tests,’ small-batches to determine the flavor profile of the specific cacao,” Paul Newman wrote in an email.

Once the cacao is roasted, it goes into “winnowing,” which strips the husks from the cacao bean and converts it into a cacao nib. The cacao bibs are then pre-refined, or crushed into a fine powder.

After the cacao is made into a powder, it is refined with sugar ad cocoa butter for hours to make smooth chocolate, and then put into a conche machine that mixes and aerates the chocolate up to 26 hours hours to develop its flavor.

After the chocolate has been conched, it is molded and tempered into chocolate bars or chips, and then packaged for customers.

Those wishing to experience the chocolate crafting process can also tour the factory, or participate in classes and workshops at the factory.

KU’L Chocolate can be purchased at select grocery stores in Bellingham or online on KU’L’s website.